Garage Openers - PFC CONTROLS | Miami, Gate Operators, Sliding Gate, Swing Gate, Intercoms, Turnstiles, Bollards, Barrier gate

- GATE ACCESS

- PEDESTRIAN ACCESS

- CONTACT US

- Main Menu

- GATE ACCESS

- PEDESTRIAN ACCESS

- CONTACT US

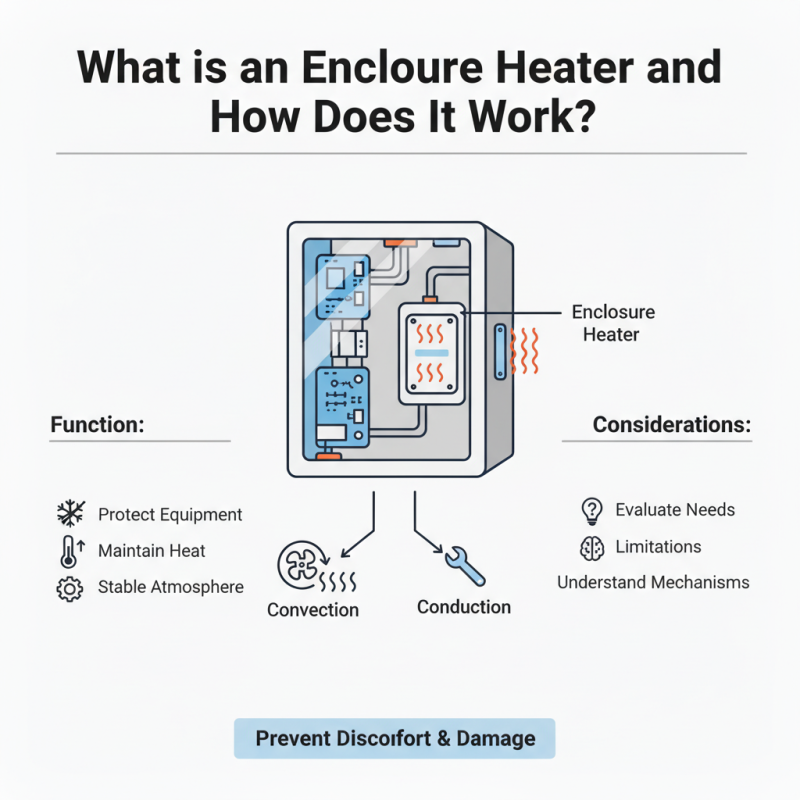

What is an Enclosure Heater and How Does It Work?

When discussing temperature control in various environments, the term "Enclosure Heater" often arises. These devices are integral in maintaining consistent heat levels in enclosed spaces, especially during cold seasons. An Enclosure Heater usually heats small areas, protecting sensitive equipment or materials from the damaging effects of extreme cold.

Understanding how an Enclosure Heater operates can provide insights into its relevance in numerous industries. By using either convection or conduction, these heaters create a stable atmosphere. However, relying solely on one type of heater might not always meet the specific heating needs of every situation. Users should evaluate their individual requirements and potential limitations in using an Enclosure Heater. A deeper understanding of its mechanisms can prevent discomfort during usage. Thus, it's crucial to consider all aspects of these heaters before deciding on their incorporation into a heating strategy.

What is an Enclosure Heater?

Enclosure heaters are essential devices used to maintain a stable temperature in various settings. They provide heat within confined spaces, ensuring equipment and materials remain functional during colder months. These heaters are widely used in industrial, commercial, and residential applications. According to the latest industry reports, nearly 80% of manufacturing facilities utilize these heaters to prevent frost damage and maintain equipment efficiency.

The operation of an enclosure heater is straightforward. Typically, they use electrical resistance or forced air to generate warmth. This technology allows them to quickly reach desired temperatures and maintain them effectively. Many models integrate thermostats, enhancing efficiency by adjusting output based on the ambient temperature. This can lead to energy savings of up to 30%, which is significant for businesses aiming to reduce operational costs.

Tips: When choosing an enclosure heater, consider the space size and heating requirements. Always ensure proper ventilation to avoid overheating. Additionally, regularly inspect the heater for any signs of wear. This maintenance practice can prevent unexpected failures and extend the heater's lifespan. Be mindful of energy consumption and select models that offer efficiency ratings for better performance and savings.

Types of Enclosure Heaters and Their Applications

Enclosure heaters come in various types, each catering to specific needs. Convection heaters are popular for many applications. They circulate warm air within an enclosed space. This helps maintain a stable temperature. You can find them in industrial settings, where consistent warmth is crucial.

Radiant heaters offer another option. They emit infrared radiation, warming objects directly rather than the air. This is useful in spaces with high ceilings. These heaters can quickly provide comfort in cold environments. However, they may not be ideal for larger areas, as their heating effect diminishes with distance.

Another type is the ducted heater. This type distributes warm air through a network of ducts. These systems are efficient for larger sections of a building. But, if not maintained properly, they can lose efficiency. Cleaning the ducts regularly is essential. Finding the right enclosure heater can be challenging. It requires careful consideration of space, size, and heating needs.

How Enclosure Heaters Function Mechanically

Enclosure heaters are essential for maintaining optimal conditions in various environments. They work by providing controlled heat. This helps protect sensitive equipment from harsh temperatures. Many industrial settings use these heaters to ensure proper functionality. They often include fans for air circulation, ensuring even heat distribution.

Mechanically, enclosure heaters operate on a straightforward principle. They convert electrical energy into heat through resistive heating elements. When electricity passes through these elements, they get hot. Fans may also circulate warm air, preventing hot spots and promoting balance. The design typically allows for easy installation in different enclosures.

Despite their usefulness, enclosure heaters can present challenges. Users must monitor temperature levels to avoid overheating. Damage may occur if a unit malfunctions. Regular maintenance is necessary to ensure effectiveness. Observing these aspects is crucial for optimal operation, though considerations are often overlooked.

Temperature Regulation of Enclosure Heaters

This bar chart illustrates the energy consumption of enclosure heaters at various temperature settings. As the temperature increases, the energy consumption also rises, highlighting the relationship between temperature regulation and energy usage in heating systems.

Key Benefits of Using Enclosure Heaters

Enclosure heaters are essential for maintaining optimal temperatures in various settings. They are commonly used in industrial applications, outdoor locations, and storage spaces. The main goal is to protect sensitive equipment and materials from extreme temperatures. This functionality is especially crucial in areas where temperature fluctuations can cause damage.

One key benefit of using enclosure heaters is energy efficiency. They provide targeted heating, which reduces energy consumption. These heaters can often be automated to turn on only when necessary. This not only saves energy but also extends the life of the equipment. Additionally, enclosure heaters help prevent condensation and corrosion. Moisture can severely damage electrical components. By keeping the space dry, these heaters maintain equipment reliability.

Another advantage is versatility. Enclosure heaters come in various sizes and styles, making them adaptable to different environments. From small control panels to large storage units, there’s a suitable option for each need. However, it’s crucial to choose the right heater for your application. An oversized unit may lead to unnecessary costs, while an undersized one may not offer adequate protection. Each situation calls for careful consideration and planning.

What is an Enclosure Heater and How Does It Work? - Key Benefits of Using Enclosure Heaters

| Feature | Description | Benefits |

|---|---|---|

| Temperature Control | Maintains a consistent temperature within the enclosure. | Prevents equipment damage and ensures optimal performance. |

| Energy Efficiency | Designed to use energy sparingly while providing adequate heating. | Reduces operational costs and environmental impact. |

| Compact Design | Easily fits into various enclosure sizes. | Saves space and allows for flexible installation options. |

| Durability | Constructed from robust materials to withstand harsh environments. | Long lifespan and reduced maintenance requirements. |

| Safety Features | Includes automatic shut-off and overheating protection. | Enhances user safety and minimizes fire risks. |

| Versatility | Suitable for a range of applications, from industrial to residential. | Adaptable to various heating needs and situations. |

Installation and Maintenance of Enclosure Heaters

Enclosure heaters are vital for maintaining optimal conditions in sensitive environments. Proper installation is crucial for their effectiveness. When installing an enclosure heater, consider the specific requirements of the space. Placement plays a significant role in heat distribution. Ideally, heaters should be installed away from airflow obstructions to ensure uniform heating. According to industry reports, incorrect placement can lead to energy waste and uneven temperature control.

Maintenance is equally important. Regular checks are necessary to ensure efficient operation. Dust and debris can accumulate, affecting performance. Research shows that a poorly maintained heater can lose up to 25% of its efficiency over time. It is recommended to clean the heater monthly, depending on the environment.

Moreover, monitoring the heater system can prevent larger issues. Some users neglect to track performance metrics, leading to unexpected failures. Routine inspections should include checking for electrical connections and ensuring that thermostat settings are accurate. Attention to these details can save time and money in the long run.